Preserve your investment, reduce your carbon footprint and save on operating costs.

Our platform is to provide a wide range of offerings to its customers from guaranteed maintenance agreements to complete system installations. VTM is committed to provide its services in a most responsive and highly competent manner, while maintaining open communication with its customers. Through this approach and a company-wide attitude of always trying to have performance meet or exceed the customers’ expectations, VTM continues to prosper. Committed to excellence in performance through preventive maintenance programs tailored to meet your facility requirements. Our unique approach is a proven method in the reduction of untimely and costly mechanical failures.

WHAT WE DO FOR YOU

District heating

District heating also known as heat networks or teleheating. It is a system for distributing heat generated in a centralized location for commercial heating requirements such as space heating and water heating, throughout the entire space.District cooling

District cooling delivers chilled water to buildings like offices and factories needing cooling. In winter, the source for the cooling can often be sea water, so it is a cheaper resource than using electricity to run compressors for cooling.Control System

A control system is a device, or set of devices, that manages, commands, directs or regulates the behaviour of other devices or systems. Industrial control systems are used in industrial production for controlling equipment or machines.Thermal Comfort

Maintaining thermal comfort for occupants of a building whether commercial or residential, is one of the important goals of VTM Mechanical. The thermal environment is important because it influences productivity and health.Now is the time to make your business or home perfect!

VTM Mechanical works!

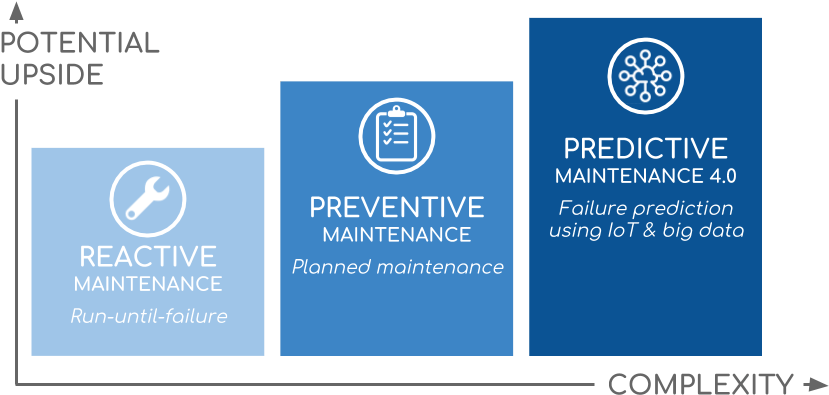

Preventative Maintenance

- Check equipment condition

- Check fan motor and amperage

- Check safety controls, set points and function

- Check operating controls, set points and function

- Check thermostat operation

- Check evaporator and condenser coils

- Check refrigerant charge

- Check access panels to be secure and rain proof

- Check fresh air intake

- Check for noise and vibrations

- Check pulleys for wear

- Check fan assembly

- Check fan belts for wear

- Change filter media where applicable

- Check equipment condition

- Check safety controls, set points and function

- Check operating controls, set points and function

- Check for noise and vibrations

- Check pulleys for wear

- Check fan assembly

- Check fan belts for wear

- Change motor amerage

At least once a year, we suggest that homeowners schedule a professional tune-up for the central heating and cooling system in their home. Inspections on boiler and furnace systems should include duct work, pipes, dampers, valves, the chimney, registers, radiators, pumps, blowers, fuel lines, the gas meter, oil tank and every part of the actual furnace and boiler. Meanwhile, heat pump and air conditioning unit inspections should also include inspections of the fan, compressor, indoor coils, outdoor coils and refrigerant lines.

20 Years Experience!

Having started in the business at the turn of the century, we have seen many trends in Heating, Ventilation and Air Conditioning. Here are just a few numbers to prove our success and experience in the field.

500

+ Air Conditioners installed

700

+ Heating Tanks installed

400

+ Boilers & Storage tanks installed

600

+ Exhaust & Air systems installed